Faswall ICCF Wall Blocks Technical Information

Faswall ICCF Wall Blocks Technical Information

Below is the short form of our technical information. If you're planning on building with Faswall we recommend you:

1. Start with our Get Started Download package including important information about how to get started with Designing and Building with Faswall.

2. That email will give you information on how to access to our full Faswall Design and Installation manual.

Then when you've got a preliminary design;

3. Request a BUDGETARY Cost Estimate (based on your design) and

4. Schedule a Design Review with your assigned rep.

5. Before you build, you MUST get and follow our Technical Design and Installation Manual. You can access this thru your Get Started email, or by using our Contact us form.

Be sure to specify that you need the "Manual and Installation Instructions". We will contact you to get further information

Faswall Natural Building Materials: Composite ICF

Faswall® is an insulated concrete form (ICF) that is made from portland and slag cement coated mineralized wood chips instead of polystyrene foam. This woodchip/cement ICF block is free draining, very porous, alkaline, and highly hygroscopic. These qualities do not allow the growth of fungus and mold which are the agents that rot and deteriorate wood fiber.

Rated Life:

Switzerland rates the woodchip/cement block a 300 year building material.

Weight:

Each block weighs approximately 28-30 pounds. Almost anyone can build with Faswall, reducing labor costs, and making DIY easier.

Size:

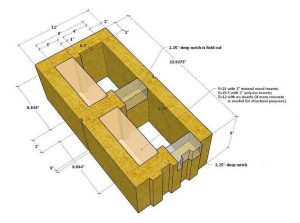

The standard wallform; part no. 1224-STD. Measures 24” long (L) x 12” wide (W) x 8”high (H) and is designed to hold a up to a 3” thick mineral wool or foam insert.

Tolerance:The WFs are trimmed to height at the factory within a tolerance of 1/16”.

Faswall® wood-cement forms consist of 85 % wood and 15% cement binder and like any woodbased product wall forms will shrink or expand during the curing process (about 28 days).

Once cured, the dimensional tolerance of the wall forms is consistent. Wall forms can withstand the moisture and temperature fluctuations occurring on a construction site over many months and even years.

Wallforming- Block Structure:

Dry Stacked, no Mortar required

The Natural ICF blocks are dry-stacked to build a wall system without the need for mortar. Each block weighs approximately 28-30 pounds. This weight, the striation of the cement-wood chip composite, and the interlocking ends of each wallform, create a stable wall even prior to the concrete infilling. Block Structure Basic Wallforms

NOTE: Faswall ICCF Blocks are designed to be filled with concrete and are not intended to stand alone as load bearing blocks.

When stacked, Faswall® ICF Blocks provide the framework for a reinforced concrete post and beam wall (see Figure 1). The post and beam system is referred to as a “screen-grid” (SG) wall system. A horizontal core is formed at 16” centers vertically in the Faswall® ICF wall system.

Insulating Values: (Highly insulating, High Performance)

Concrete filled Faswall wall with 3” mineral wool inserts, interior plaster, exterior stucco coating

R-21 U-Value .048

Concrete filled Faswall wall with 3” polyisocyanurate foam inserts, interior plaster, exterior stucco coating

R-25.5 U-Value .039

Concrete filled Faswall wall with NO additional insulation.

R-11.8 U-Value .085

Designing with Faswall - General Principles

The ideal Faswall design results in little to no cutting of the composite ICF Blocks More on Designing for Faswall

Rule #1: Design all wall runs to the foot using odd numbers: e.g.: 5’, 15’, 17’, 33’ long walls. Even for bumpouts USE odd numbers to the foot.

Rule #2: Layout all openings on a one foot increment from the corners of each wall run.

Rule #3: Design all openings using a 12” increment horizontally and 8” increment vertically. (exception are standard door rough openings which are typically not in the 12” x 8” increment.

Rule #4: Use Faswall as the rough opening for the attachment of windows and doors in lieu of installing permanent wood framework at each opening.

Following these simple instructions will result in:

- Least amount of waste of product.

- Very little, if any, permanent lumber.

- Fastest installation (far less cutting of block).

- Perfect alignment of the wall forms insuring straight, plumb walls with no compromise of the structural concrete infill.

Find a Faswall Designer

Engineering

Faswall structures are usually engineered. Typcially, ACI 318 is the basis for an engineered solution. Faswall® formed concrete structures may be utilized for 1-3-story buildings such as; residences, motels, schools and commercial buildings. In addition they serve well for such structures as firewalls and retaining walls. They can also be engineered for use in specific locations in high-rise buildings. More complete engineering data is available from ShelterWorks that includes physical testing of the wallforms, load tables, fire testing, termite testing, acoustical testing, etc.

Find a Faswall Engineer

Fire Resistance

Exceptionally fire resistant. The fire rating of Faswall® wall construction materials is 4 hours with zero flame spread and no smoke development (ASTM C-119-88, E-84-89a; test done without insulation inserts). Faswall® walls cannot sustain a fire, and there is no release of toxic smoke from Faswall® walls during a fire.

Sound Proofing

Faswall® wall forms are sound Proof (ASTM E 90-90) with an STC rating of 55.

Tools and Materials needed to install Faswall®

Faswall is worked with standard Tools:

- Circular saw or miter saw 7” – 12” diameter with carbide blades for specialty cutting.

- Reciprocating saw with 12”-16” pruning blade for rough cutting the Wallforms.

- Electric chain saw is very useful.

- Electric rotary sander/grinder to level out small irregularities.

- Rubber mallet for positioning wall forms prior to filling is an essential tool.

- Cup Bits for drilling holes for ledger boards

- Cordless drill and appropriate selection of bits for driving fasteners.

- Level, string, plumb bob to assure a plumb and level wall.

- Adequate moveable set of scaffolding system in proportion to the job

- Rebar bending, fastening, and cutting equipment

WARNING: Protect eyes with safety glasses and mouth & nose with dust mask when

cutting Faswall® forms!

Materials:

- Wood: For temporary wood bucks (frames) at each opening use 2x10 lumber for the

sides and header and two 2x4’s on edge for the sill. 2x lumber or ply wood is needed

to form corner boards at wall corners.

- Plywood; 4’ x 8’ sheets to be used to fabricate temporary strengthening cover plates

and coarse threaded fasteners (#9 x 3” deck screws) for applying to weakened areas

of the wall or cut/altered block.

- Wood shims for occasional leveling of courses (usually not necessary). Plastic shims

for leveling the first course if that approach is selected

- Fasteners; coated deck screws. #9 x 3” and #9 x 3.5” for fastening corner units, for

modifying wallforms, for fastening bucks and stabilizing plywood to the wall forms.

- Mortar mix (as the first row may be laid in mortar). A professional mason is best

qualified to do this, since it is very important that the first row be perfectly level to

build up the wall.

- Construction adhesive such as “Concrete Repair” (gray), Polyurethane Concrete &

Masonry Sealant (gray), “Liquid Nails”, or nonexpanding urethane foam to fill small

gaps or secure a wallform that has been cut. Such adhesives should be used only as a

supplement to the patching

Setting the Forms

Before workers begin to lay out the Wallforms on the building perimeter, they must understand that the forms are not conventional concrete blocks.

Installers need to carefully study the detailed installation guide and the accompanying diagrams and illustrations. If there are any questions about the proper use of Faswall® Wallforms, do not hesitate to contact the Faswall® Wallform manufacturer. In order to realize all the benefits and advantages of the system, it is vitally important that the system be used correctly.

Foundations-slabs shall be designed/engineered and constructed in accordance with all applicable building codes and ordinances as well as engineers specifications if an engineer’s involvement is required.

Windows + Doors

The preferred method is to fasten windows and doors directly into the wall form material. The End Blocks and Half Blocks are designed to build openings as they have smooth ends to which windows can be fastened with screws.

Floors

When an intermediate floor system is designed into the FASWALL® Wallforms structure, it is generally assumed to be of wood. Because these floors do not have components that can adequately support the dead weight of the subsequent wall assembly above it, the typical design criterion is to “hang” the floor from the inside of the wall structure.

Fastening to the Wallforms.

Mechanical fasteners appropriate for the weight of the item to be attached should be anchored directly into the concrete core. For lighter loads coated #8 or #9 deck screws can be used if the depth of penetration into the wallform is maximized. Fastening screws at points where the wallform web is present is preferable as you can penetrate deep into the wallform at that point using 3.5-4” screws.

Electrical  + Plumbing

+ Plumbing

Surface Finishing

Stucco, Plaster, Vapor Wrap, Siding + More

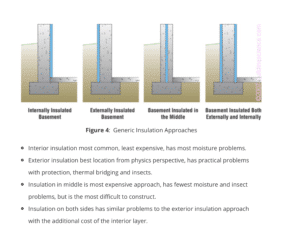

Below Grade Surface Treatments of Faswall® Wallforms

Below grade wall surfaces outside of living space must be parge coated and waterproofed.

For some applications without living space inside, such as frost foundations, a parge coating is sufficient when used in conjunction with an adequate drainage system. Equally important to the effectiveness of any waterproofing system is adequate drainage. There are several products available to provide “in-plane” drainage throughout the full height of the basement wall. These, coupled with properly designed footing drains, will take the water away before it has the chance to become a problem

“We did a lot of research on various green building systems but settled on Faswall. Not only did it seem like the “greenest” technology, but the ease of building compared to other systems seemed like a good choice for an owner/builder. What we didn’t expect, but were totally delighted with, was how knowledgable and helpful the people at Faswall were. We couldn’t have done it without you!”

-Ted and Donna Havecheck

I Want To Get Started

Request Your Free Download "Get Started" Package:

includes: Design ideas, Product Data Sheet, Block Pricing, Technical and Installation Info, Engineering Details

Home Owner

Builder/Developer

Architect/Engineer

Educator/Student

Building Dept./Government

You’d be surprised at the various types of homes and commercial buildings that can be built with Faswall. Check out some of the recent projects..

Photo Gallery

+

+