Faswall is part of a revolution in mold-resistant building materials and design choices for mold-free construction. To understand why Faswall is one of the best materials to have in your arsenal for mold-resistant building, we have to back up to mold: how it develops, and what material and design choices are best for fighting it.

The Problem of Mold

Mold reproduces by releasing spores, tiny particles that can be invisible to the naked eye. These spores can travel through the air, or pass from surface to surface through contact transmission, and are almost impossible to keep out of an environment. Fortunately, they’re harmless at this scale. However, this means that mold cannot be eradicated at the source, it can only be prevented from growing by depriving it of the conditions it needs to develop.

Unlike plants, mold does not require sunlight, only a food source, and water. Most varieties of mold are distinguished by what they eat. When you add them up, molds eat almost anything, from organic compounds like dust, wood fiber and fabrics, to some synthetic compounds found in paints and adhesives. In addition to causing allergic reactions in people, mold actively decomposes whatever it is eating, deteriorating the strengths of materials and often causing an odor.

Even materials that mold can’t eat, like glass, can provide conditions for mold to thrive. Mold often develops around basement windows, where condensation on the glass leaves moisture on the surrounding wood or drywall.

It’s clear that the best weapon against mold is controlling moisture, but this is where opinions have varied about what effective moisture control looks like.

Sealing Works Both Ways

Many of the structures in the U.S. were built with a mindset that the tighter the seal, the better. These buildings use HVAC systems to control interior moisture and refresh the air inside. As long as there is adequate drainage and the building is waterproof, mold won’t be a problem inside. However, any moisture that penetrates the building material will be trapped there, unable to evaporate.

The lifespans of such buildings are usually measured in decades. Water almost inevitably finds a way in, through vapor diffusion, driving rain, condensation, or even negative pressure caused by wind pulling water into gaps in the structure’s protection. Water that is sealed into the building or penetrates into its substrates poses a risk of inaccessible decay.

Breathability

Breathability is as old as building construction. People have always needed to consider ventilation and moisture, and for the most part managed to avoid getting mold poisoning despite not having HVAC systems.

Much of traditional ventilation is done through opening doors and windows, (“letting fresh air in”) but this causes and energy penalty when the home is being heated or cooled. But there’s another solution: breathability.

The more vapor permeable a material is, the more water vapor is able to pass through it.

Breathability describes how structures built with vapor permeable materials naturally regulate internal humidity and release trapped moisture. Breathable rooms are most recognizable because they lack the “basement smell” that occurs when rooms can’t naturally expel accumulated moisture and don’t have enough supplemental ventilation. This is how buildings made before modern sealing survived wet conditions. They breathed well, and so did the people in them.

The problem of porous material and breathability by themselves appears when the weather gets bad. Prolonged wet, flooding, and cold cause build-up of moisture. The material itself needs to be able to withstand the wet for as long as it takes to get dry again, without deteriorating each time, and without trapping water.

Additionally, the structure needs to drain water away from its walls to allow the water in them to evaporate.

Where We Come In

The solution lies in a mix of modern waterproofing and drainage, and a return to a more traditional breathability using vapor permeable materials. The last of these is Faswall’s special asset.

By combining Faswall with waterproofing coats and a good drainage system, you can design a building to last centuries, not decades.

Mold-Resistant Materials to Combine with Faswall

Spray-on stucco:

https://faswall.com/quick-way-apply-stucco-faswall-home/

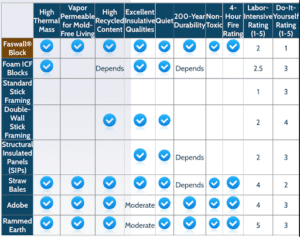

Faswall vs. other Mold-Resistant materials

Compared to concrete, Faswall ICF eliminates the damp/dank smell and feel of a traditional basement. Wood fiber cement is vapor permeable and provides an air quality that is fresh, a temperature that is moderated, and a relative humidity that is constant. The indoor environment does not support fungal growth and spores. Our blocks create a finished wall surface on the inside which does not need to be filled out and insulated (unlike a poured concrete basement).

The Faswall ICF surface can be left as is and trimmed if desired, thereby creating an attractive surface that fits your vision.Plus, it’s cost effective! A Faswal ICF-built basement will cost approximately the same as building a poured concrete wall basement, assuming that interior wall was to be finished.

We’re Passionate About Our Purpose

One of Rich’s main concerns was building in an environmentally-friendly fashion. He was pleased to learn that Faswall block is one of the greenest building products on the market. Not only would he get the solid foundation he needed with our blocks, but he would be doing good for the environment as well.

One of the great things about Faswall’s wood/concrete composition is that the blocks will not grow mold. However, there is still a danger that water can leak into parts of the structure that are below grade, leaving you with standing water in the basement.

Builder Mark Maricle has demonstrated an easy way of preventing this. Wherever the blocks are below grade, he applies a scratch coat of three parts sand, one part Portland cement to the Faswall blocks. A vapor-permeable waterproofing material is brushed on top of that, followed by a dimpled membrane and a layer of landscape cloth. All these products should be available at lumber or building supply stores, and they’re all simple to attach to Faswall green building blocks. “Any moisture that hits the side of the wall will . . . shed down to our perimeter drain and go out to daylight,” Mark says – keeping it away from your foundation and your home.”

Though we could talk about the benefits of using Faswall blocks all day long, we’ll let our product speak for itself. Order a sample to see the benefits, and understand the passion behind our design.